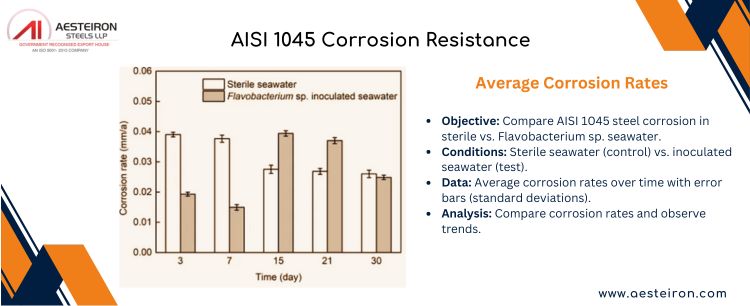

Understanding the chemical composition of SAE 1045 steel is crucial as it directly influences the mechanical properties of the material. The following table provides an overview of its chemical composition: Table of Contents Chemical Composition of SAE 1045 Steel One of the key advantages of AISI 1045 steel is its excellent weldability, which allows for high-quality welds that are strong, durable, and safe. Proper welding procedures can prevent damage such as cracks, making it ideal for applications requiring significant structural integrity. Additionally, its good machinability means it can be cut with minimal tools, resulting in a superior surface finish with tight tolerances. This efficiency leads to faster production times and reduced manufacturing costs. Finally, its high strength properties make it both safer and more durable, suitable for construction and applications where heavy loads and harsh conditions are present. Weldability of ASTM 1045 Steel Mechanical Properties of AISI 1045 Steel - Cold Drawn Normalized condition offers several benefits, including enhanced mechanical properties, reduced internal stress, improved machinability, and refined grain structure, making it a preferred choice for many applications. Heat Treatment of DIN 1.1191 Steel SAE 1045 Steel vs. 4140 Steel Properties of Quenched and Tempered SAE 1045 Steel The following equivalent grades of Steel 1045 provide insight into how this material is categorized under different international standards. Equivalent Grades of AISI 1045 Steel Thermal Properties of SAE 1045 Steel Tolerances of AISI 1045 Carbon Steel At these temperatures, the material softens, improving its machinability and enhancing its malleability. After annealing, the material is cooled gradually in a furnace to achieve the desired mechanical properties tailored to specific applications. Annealing Process of CK45 Steel Quality Assurance for Steel 1045 This material tends to corrode easily when exposed to moisture or aggressive environments like acids and salts. To mitigate corrosion, additional protective coatings or regular maintenance are often necessary. Corrosion Resistance of AISI 1045 Steel Electrical Characteristics of JIS S45C Steel Applications of SAE 1045 Steel condensator and evaporator condensator of car Xinxiang Yukun Refrigeration Technology Co.Ltd , https://www.yukunevaporator.com

Grade

C

Si

Mn

P

S

1045

0.43-0.50

0.15-0.35

0.60-0.90

≤0.04

≤0.05

AISI 1045 Steel Offers Excellent Weldability, Machinability, and High Strength

Aspect

Details

Welding Conditions

Proper welding techniques are required for successful joining.

Electrodes

Use low-hydrogen electrodes to minimize defects.

Pre-heating

Pre-heat the workpiece to 200°C – 300°C (392°F – 572°F).

Welding Temperature

Maintain pre-heat temperature throughout the welding process.

Cooling

Cool the material slowly using sand or ash to manage the cooling rate.

Stress Relief

Perform stress relief at 550°C – 660°C (1022°F – 1220°F).

Mechanical Properties

Hardness, Brinell

Hardness, Rockwell B

Hardness, Vickers

Tensile Strength, Yield

Tensile Strength, Ultimate

Elongation at Break (in 50 mm)

Reduction of Area

Poisson’s Ratio

Modulus of Elasticity

Bulk Modulus

Shear Modulus

Metric

184

84

170

310 MPa

565 MPa

16.00%

40.00%

0.29

200 GPa

140 GPa

80 GPa

Imperial

184

84

170

45000 psi

81900 psi

16.00%

40.00%

0.29

29000 ksi

20300 ksi

11600 ksi

DIN 1.1191 Steel is Typically Available in Black Hot Rolled or Normalized Forms

Process

Heating Temperature

Cooling Method

Forging

850°C – 1250°C (1562°F – 2282°F)

Cool in a furnace

Annealing

800°C – 850°C (1472°F – 1562°F)

Cool in a furnace

Normalizing

870°C – 920°C (1598°F – 1688°F)

Cool in still air

Stress-Relieving

550°C – 660°C (1022°F – 1220°F)

Cool in still air

Hardening

820°C – 850°C (1508°F – 1562°F)

Quench in water or brine

Tempering

400°C – 650°C (752°F – 1202°F)

Cool in still air

Property

SAE 1045 Steel

SAE 4140 Steel

Type

Carbon Steel

Alloy Steel

Carbon Content

0.43-0.50%

0.40%

Manganese Content

0.60-0.90%

0.75-1.00%

Chromium

None

Present

Molybdenum

None

Present

Iron (Fe)

98.51-98.98%

96.79-97.78%

Phosphorus (P, max)

0.04%

0.035%

Sulfur (S, max)

0.05%

0.040%

Strength

Good strength and impact resistance

Superior hardness and toughness

Common Uses

Machinery parts, automotive components

Axles, gears, shafts

Characteristics

Moderate hardness and strength

Enhanced wear resistance and toughness

Section Size (mm)

Up to 16mm

17-44 mm

41-100 mm

Tensile Strength (MPa)

700-850

650-800

630-780

Yield Strength (MPa)

500

430

370

Impact Charpy (J)

30

30

30

Elongation in 50 mm (%)

14

16

7

Hardness (HB)

210-245

195-235

185-230

Explore the Equivalent Grades of Steel 1045

Country

USA

British

Japan

Australia

Standard

ASTM A29

EN 10083-2

JIS G051

AS 1442

Grades

1045

C45/1.1191

S45C

1045

Properties

Metric

Imperial

Thermal Conductivity

51.9 W/mK

360 BTU in/hr.ft².°F

Thermal Expansion Coefficient (@0.000-100°C/32-212°F)

11.2 µm/m°C

6.22 µm/m°C

Surface Finish

Black-Forged

Turned

Black-Rolled

Peeled

Ground

Polished

Cold Drawn

Tolerance

(0, +5mm)

(0, +3mm)

(0, +1mm)

Best H11

Best h9

Best h11

Best H11

Annealing Temperature for JIS S45C Grade Ranges From 790-870 °C

Aspect

Details

Purpose of Annealing

Softens surface hardness for improved machinability

Annealing Temperature

820°C to 840°C

Holding Time

Sufficient time at annealing temperature

Measured Surface Hardness

Typically below 200 HBW (Brinell Hardness)

SAE 1045 Steel is Not Highly Resistant to Corrosion in Harsh Environments

Feature

1045 Steel

Primary Composition

0.45% Carbon, Iron

Corrosion Resistance

Low

Protective Layer

Does not form a protective chromium oxide layer

Exposure to Harsh Environments

Prone to rust and corrosion in saltwater, acids, and bases

Maintenance Requirements

Requires coating or treatment for better resistance

Typical Applications

Structural components, machinery, automotive parts

Electrical Properties

Metric

English

Comments

Electrical Resistivity

0.0000162 ohm-cm @ 0.000 °C

0.0000162 ohm-cm @ 32.0 °F

Annealed specimen

0.0000223 ohm-cm @ 100 °C

0.0000223 ohm-cm @ 212 °F

Annealed specimen

Pins

Gears

Rams

Ratchets

Bolts

Light Gears

Rolls

Shafts

Sockets

Spindles

Axles

Worms

Crankshafts

Studs

Guide Rods

Torsion Bars

Connecting Rods

Hydraulic Clamps

SAE 1045 Steel Chemical Composition

Certainly! Here's a revised and expanded version of the content in English:

---

---

This rewritten version maintains the original information while expanding on certain sections to reach the desired word count.

Next Article

SAE 1045 Steel Chemical Composition