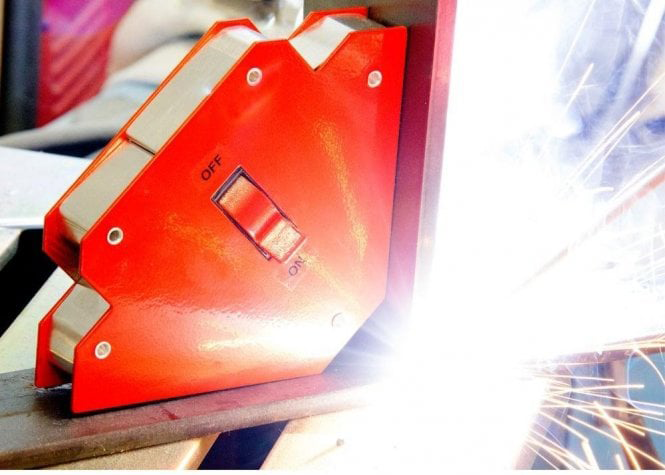

Welding is essentially the process of fusing two pieces together using heat, pressure, or both to create a solid joint as they cool down. But maintaining a stable position for metal components during welding can be quite a challenge—this is where magnetic welding clamps prove indispensable. Magnetic welding clamps are specialized tools designed to hold metal workpieces firmly in place during welding operations, even when dealing with intricate shapes and difficult angles. These clamps utilize powerful magnets to keep the pieces from shifting while you focus on the welding task at hand. Below, we’ll explore how these clamps operate and why they’re so beneficial for welders. Our magnetic welding clamps consist of a ferrite magnet and a clamp assembly. Ferrite magnets are renowned for their exceptional strength, excellent heat resistance, and cost-effectiveness. The clamp itself serves to stabilize the workpiece, while the magnet locks onto the clamp, ensuring a firm grip against the metal surface. The ferrite magnet generates a robust magnetic field that keeps the workpiece steady, enabling welders to concentrate fully on the welding process without worrying about movement or slippage of the material. Some advanced models come equipped with a mechanical switch, allowing users to toggle the magnet’s magnetic field on and off. This feature makes positioning the clamp much more precise, as there’s no residual magnetic pull to interfere with adjustments. Additionally, cleaning the magnet becomes straightforward when it’s switched off—any accumulated metal shavings or debris can be easily wiped away. Reliable Grip The primary advantage of magnetic welding clamps lies in their unmatched ability to maintain a secure hold on metal workpieces throughout the entire welding procedure. This is particularly advantageous when working with complex geometries or awkward orientations, situations where conventional clamps often fall short in terms of providing adequate support. User-Friendly Another compelling reason to choose magnetic welding clamps is their simplicity of use. Attaching them to your workpiece is quick and effortless, and they can be easily repositioned as needed. This flexibility makes them suitable for a wide range of welding projects, from small repairs to large-scale fabrication tasks. No Surface Damage In contrast to standard clamps, magnetic welding clamps do not mar or damage the workpiece because they apply no direct pressure to the surface. Instead, they rely solely on the magnetic force to keep the piece steady. Versatility at Its Best Magnetic welding clamps outshine traditional clamps in versatility. They function seamlessly on various metal surfaces, including curved and irregular ones, and are compatible with multiple welding techniques like MIG, TIG, and Stick welding. Whether you're working on flat sheets or cylindrical pipes, these clamps adapt effortlessly to meet your needs. While magnetic welding clamps are generally safe to use, it's crucial to observe certain safety guidelines to prevent accidents. The intense magnetic field generated by these clamps can attract stray ferrous items such as nails, screws, or tools. If these objects get caught in the magnetic field during welding, they might dislodge and pose a hazard. Therefore, welders must ensure their workspace is clear of any metallic debris that could be drawn toward the clamp. As always, proper personal protective equipment (PPE), including gloves and safety glasses, should be worn at all times. By following these precautions, welders can enjoy the convenience and efficiency of magnetic welding clamps while minimizing risks. Overall, magnetic welding clamps represent a game-changer in the world of metalworking. Their ability to securely hold diverse workpieces under varying conditions makes them invaluable tools for both novice and experienced welders alike. With regular maintenance and adherence to safety protocols, they can enhance productivity while ensuring consistent quality in every project. Industrial Heavy Duty Pallet Rack Industrial Heavy Duty Pallet Rack,Stainless Steel Wire Rack,Chrome Steel Wire Shelf,Heavy Duty Cantilever Rack Suzhou Aomeijia Metalic Products Co,Ltd. , https://www.amjshelf.com

Understanding How Magnetic Welding Clamps Operate

The Advantages of Using Magnetic Welding Clamps

Safety Precautions When Using Magnetic Welding Clamps

Magnetic Welding Clamps: The Ideal Solution for Secure and Easy Welding

Next Article

How To Improve Your Cleaning Process

Prev Article

Air Compressor Installation Guide