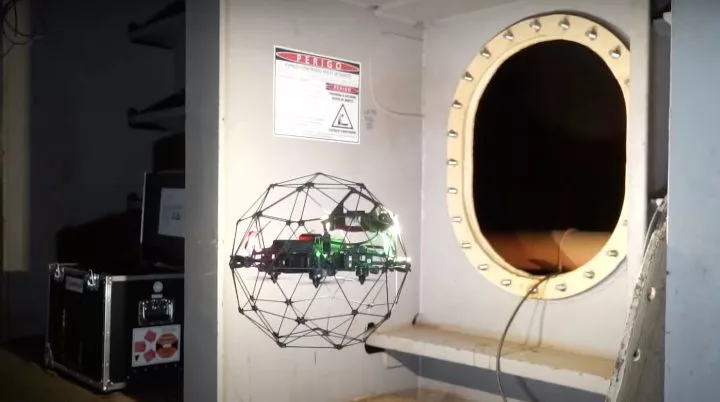

DR1 Group managed to slash the downtime for a ballast tank inspection on a drilling rig by a whopping 80% using the Elios 2. Read on to discover how this innovative solution transformed the process. Cost Savings By deploying the Elios 2, DR1 Group achieved a 60% reduction in costs for the ballast tank inspection. Time Efficiency With the Elios 2, the total inspection time dropped from five days to just one, representing an 80% decrease in downtime. Enhanced Safety The Elios 2 eliminated the need for confined space entry or rope-based inspections, making the entire process safer. Offshore drilling rigs are critical tools in the Oil and Gas industry, enabling workers to extract oil from the seabed. In shallower waters, these rigs rely on columns extending all the way to the ocean floor for support. However, in deeper waters, floating rigs are designed to stay afloat by using pontoons connected to columns at each corner. Each column houses a ballast tank, which stores water to regulate the rig's buoyancy. Similarly, the pontoons also have ballast tanks that can store either air or water to maintain the rig's balance. Given their pivotal role in the rig's stability, these ballast tanks require regular inspections to ensure they remain functional. The drilling rig inspected by DR1 Group In Angra dos Reis, Brazil, shipyard administrators sought a safer and more efficient method for inspecting their drilling rigs. Previously, inspectors had to enter the columns and ballast tanks using rope access, which was both hazardous and expensive due to prolonged rig downtime. To enhance safety and cut downtime, the shipyard turned to DR1 Group for a trial inspection using drones. This initiative aimed to demonstrate how drones could meet the shipyard's needs while ensuring compliance with safety regulations. Following an initial planning session, DR1 Group collaborated closely with the shipyard to design two test missions showcasing the potential of drones in rig inspections. These missions focused on: DR1 Group's objective was to gather sufficient visual data during these tests to convince the shipyard administrators of the feasibility of drone-based inspections. Over a span of two months, drone operators from DR1 held multiple meetings with shipyard staff to review legal requirements and compliance standards, ensuring the tests would be safe and adhere to industry norms. One team executed the external inspection using DJI’s Matrice 210, while another team tackled the internal inspection with Flyability’s Elios 2. The internal test proved highly successful, as the DR1 team managed to inspect 40% of one ballast tank in just 30 minutes of flight time. Across two hours of testing, pilots and inspectors took breaks to swap batteries and verify footage, ensuring comprehensive coverage. Based on these results, the shipyard administrators calculated that using the Elios 2 could reduce the overall internal inspection time from 60 days to just 20. Watch this video for footage from one of the ballast tank flights: After reviewing the visual data collected during the tests, the shipyard's administrators expressed immense satisfaction with the enhanced safety, efficiency, and cost-effectiveness achieved through the Elios 2. Here are some images captured inside the ballast tank: These trials on the drilling rig occurred in early 2020, shortly before all activities were suspended due to the pandemic. However, operations have since resumed, and the shipyard intends to call DR1 Group back for further inspections on the same rig. Moreover, the shipyard owns several additional rigs and is considering hiring DR1 Group to use the Elios 2 for internal inspections across all of them. Meanwhile, DR1 Group continues to deploy the Elios 2 for confined space inspections in various vessels within the Oil and Gas sector, including ballast tanks on drilling rigs and cargo tanks on FPSOs. Paper Card,Cardstock Paper,White Cardstock,Coloured Card Jiangmen Yingzhihui Electronic Commerce Co., LTD , https://www.yzhprint.comFlyability's Elios Cuts Downtime By 80% In Drilling Rig Ballast Tank Inspection

Key Benefits At A Glance

Introduction

Customer Requirements

Implementation

Outcomes

Conclusion

Flyability's Elios Cuts Downtime by 80% in Drilling Rig Ballast Tank Inspection