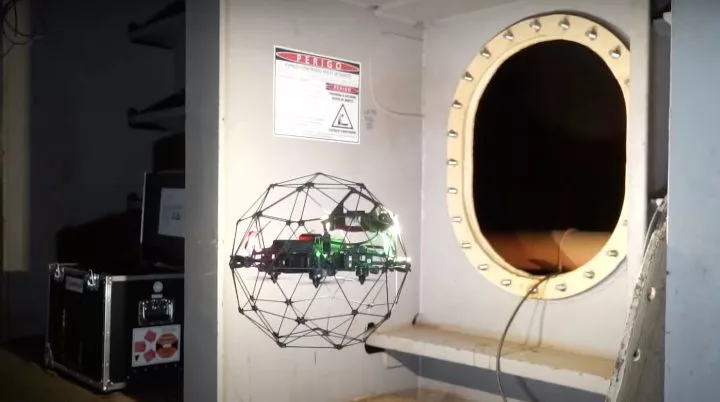

DR1 Group managed to cut downtime by 80% during a ballast tank inspection on a drilling rig by deploying the Elios 2. Read on to find out how this innovative solution transformed the process. Cost Efficiency Reduced costs by 60% compared to traditional methods when using the Elios 2 for ballast tank inspections. Time Savings Decreased total inspection time from five days to just one by using the Elios 2. Enhanced Safety Eliminated the need for confined space entry or rope access during inspections with the Elios 2. In the oil and gas sector, offshore drilling rigs are crucial for extracting oil from the ocean floor. These massive structures rely on columns extending into the water to stabilize themselves in deeper waters. Each column houses a ballast tank that helps regulate the rig's buoyancy. Similarly, pontoons beneath the rig also have ballast tanks that store air or water to maintain balance. Since these tanks play a critical role in ensuring the rig remains stable, regular inspections are essential to guarantee their functionality. The drilling rig inspected by DR1 Group These ballast tanks require frequent checks to ensure they remain in optimal condition. Traditional methods involve sending inspectors inside these confined spaces using rope access techniques, which poses significant risks and leads to prolonged periods of downtime. A shipyard located in Angra dos Reis, Brazil, sought a safer and more efficient method for inspecting their drilling rigs. Previously, they relied on rope-access techniques for such inspections, which proved hazardous and expensive due to extended rig downtime. Seeking an alternative, the shipyard administrators reached out to DR1 Group to explore the feasibility of drone-based inspections. Following initial consultations, DR1 Group collaborated closely with the shipyard to design two test missions aimed at showcasing the potential of drones in addressing their inspection needs. The missions focused on: External rig inspection, covering towers and other external structures requiring assessment. Internal rig inspection, focusing on columns and ballast tanks. The goal was to gather sufficient visual data through drone inspections to demonstrate the practicality and benefits of this approach. Over two months, drone operators from DR1 met repeatedly with shipyard staff to review legal requirements and compliance standards, ensuring all aspects of the operation were safe and legitimate. Two separate teams conducted the trials—one focusing on external inspections using DJI’s Matrice 210, while the other tackled internal inspections with Flyability’s Elios 2. The internal inspection proved particularly successful; within half an hour of flight time, the DR1 team covered 40% of one ballast tank. Overall, the entire procedure took around two hours, factoring in battery swaps and footage reviews to ensure comprehensive coverage. Based on these results, the shipyard administrators calculated that switching to Elios 2 inspections could slash the total time required for rig inspections from 60 days down to merely 20. Here’s a clip from one of the ballast tank flights: After presenting the collected visual data to the shipyard administrators, they expressed immense satisfaction with the enhanced safety, efficiency, and cost-effectiveness demonstrated by the Elios 2. Below are some images captured during the inspection: These trials commenced in early 2020 but were interrupted shortly thereafter due to the global pandemic. Nevertheless, as operations resumed, the shipyard expressed interest in engaging DR1 Group again for future inspections using the Elios 2. With several rigs under its management, the shipyard plans to expand drone inspections across all facilities. Meanwhile, DR1 Group continues to utilize the Elios 2 for various confined space inspections within the oil and gas industry, including ballast tanks on drilling rigs and cargo tanks on floating production storage offloading units (FPSOs). Food Label,Nutrition Facts Label,Milk Nutrition Label,Ingredients Label Jiangmen Yingzhihui Electronic Commerce Co., LTD , https://www.yzhprint.comFlyability's Elios Reduces Downtime by 80% During Rig Ballast Tank Inspections

Key Benefits At A Glance

Introduction

Customer Requirements

The Solution

Outcome

Conclusion

Flyability's Elios Cuts Downtime by 80% in Drilling Rig Ballast Tank Inspection