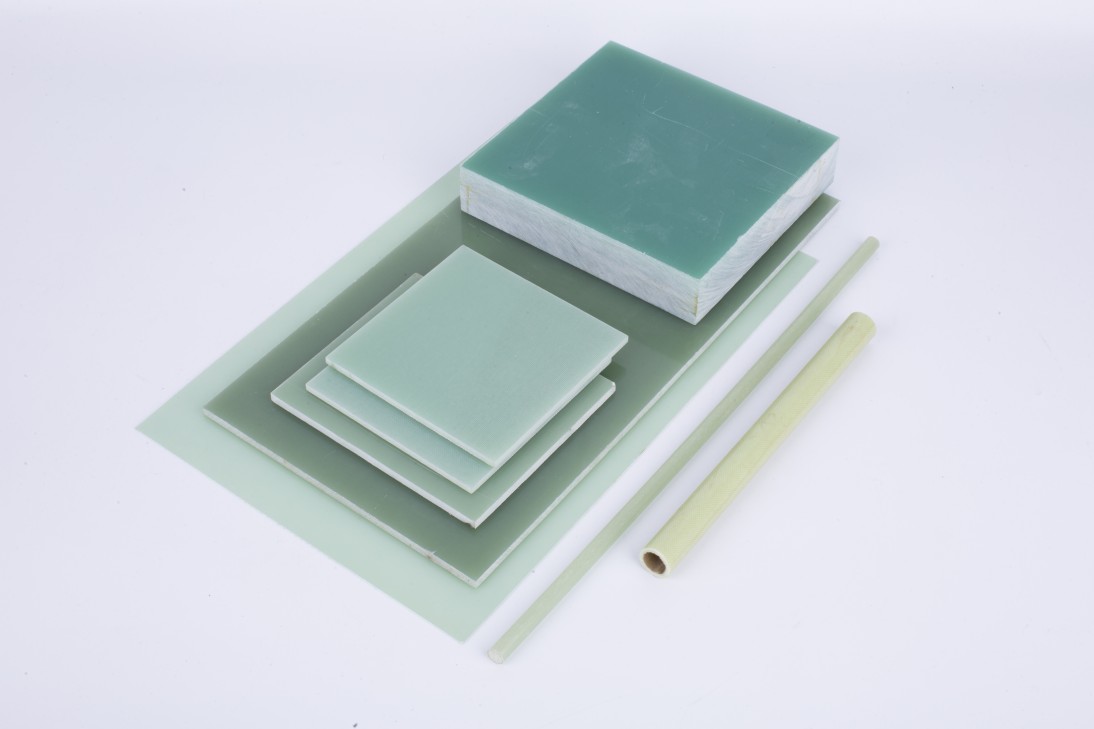

HONYEPO®G10/fr4 Epoxy Fiber Glass sheet combines a woven glass fabric and an epoxy resin laminate (tg approximately 130-c) that contains bromine. G10 provides consistent quality and good electrical properties under dry and humid conditions, as well as high flexural, impact, and bond strength at room temperatures. This product is suitable for a variety of structural, high humidity, and electrical insulation applications, which include terminal boards, lapping carriers, and disc and microelectronics polishing. Np510a complies with the requirements of mil-i-24768/27, type GF. HONYEPO®G10 / fr4 Epoxy Fiber Glass sheet feature : Higher mechanical properties. Good mechanical workability. Good heat resistance and moisture resistance. In high temperature electric performance is stable. Higher mechanical properties and dielectric properties. In the middle temperature with high mechanical properties. The flame retardant grade is UL94 V0 F grade Heat resistance and heat resistance (120 min) reaches to 180 ℃ High mechanical performances (bending, compression and stretching of transverse strength is above 330Mpa) High dielectric properties of th e oil (25 ℃ in the vertical dielectric strength of 16 kv/mm) HONYEPO®G10 / fr4 Epoxy Fiber Glass sheet application : Motors and electrical equipment insulation parts General machines parts and gear, generators, Pads, base, baffle,Generator, transformer, fixture, inverter, motor Backing boards: PCB drilling machine, Plastic Mould, Injection Mould, Injection molding machine, Table grinding machine, ICT governance Reinforcement sheets: Testing fixture PFC,FPC Less than 3 mm is used for Raw materials of PCB flexible circuit board test processing Needle plate, carrier board and insulating electrical and electronic products G10 and FR4 glass cloth reinforced epoxy natural is typically a yellowish to light green color. The most versatile all-around laminate grades are continuous glass woven fabric impregnated with an epoxy resin binder. Epoxy resins are among the most versatile and widely used plastics in the electronics field, primarily because water absorption is virtually nil, rendering it an outstanding insulator. Fr4 Fiber Glass Epoxy Sheet,G10 Fr4 Insulate Sheet,G11 G10 Fiber Glass Plate,Epoxy Fiber Glass Sheet,FR4 G10 Hony Engineering Plastics Limited , https://www.honyplastic.com

Beyond its electrical insulating properties, epoxy resins exhibit great dimensional stability (shrinkage is usually less than 1 percent) and superior adhesive properties. G10/FR4 has extremely high mechanical strength, good dielectric loss properties, and good electric strength properties, both wet and dry.

The main difference between NEMA Grades G10 and FR4 is that FR4 is a fire retardant grade of G10. Therefore, FR4 can be safely substituted where G10 is called for, while G10 can never be substituted where FR4 is called for. G10 meets MIL-I-24768/2 GEE and FR4 meets MIL-I-24768/27 GEE-F.

G9 has good mechanical properties plus high resistance to flame, heat, arcing, and most strong alkali solutions. It is recommended for use where good mechanical properties are needed under wet conditions. Specification: MIL-1-24768/1, Type GME .

HONY plastic also CNC to your CAD drawing, cut to size to +-.005 tolerance, and sell full sheets in quantity. This G10 and FR4 material is also available thinner and thicker as well as in rod and tube. Please call our sales department for information.

Tube Cutter CT-312 for 1/4"~1-5/8" O. D. Tubing, Copper Tube Cutter

**Product: Tube Cutter CT-312**

**Model No.:** CT-312

**Size:** Aluminum Alloy Body

**Trademark:** RESOUR/COOLSOUR

**Transport Package:** Carton

**Specification:** 1/4" ~ 1-5/8" (6~42mm)

**Origin:** Zhejiang, China (Mainland)

**HS Code:** 3824909990

---

**Description:**

The Tube Cutter CT-312 is a versatile and durable tool designed for cutting various types of tubing, including copper, steel, stainless steel, and aluminum. It is ideal for use in plumbing, HVAC, and industrial applications where precision and efficiency are essential.

**Material:**

The CT-312 features an aluminum alloy body, ensuring lightweight handling without compromising on strength or durability.

**Features:**

- Efficiently cuts tubing with a clean, straight, and burr-free finish.

- Designed to prevent chips or debris from clogging the tubing.

- Equipped with polished steel rollers and a flare cut-off groove that securely holds the tube in place during cutting.

- Suitable for tubing with an outer diameter ranging from 1/4" to 1-5/8" (6mm to 42mm).

- Easy to use and maintain, making it a reliable choice for both professionals and DIY users.

**Images:**

[Image of Tube Cutter CT-312]

[Another Image of Tube Cutter CT-312]

[Additional Image of Tube Cutter CT-312]

This high-quality tube cutter is perfect for anyone needing a reliable, precise, and long-lasting cutting solution. Whether you're working on a small project or a large-scale installation, the CT-312 delivers consistent performance and excellent results every time.

Prev Article

Zinc Clip-On Wheel Balance Weights