Green glycol from renewable resources

The development of diol technology from renewable resources has become a key focus under China's "Eleventh Five-Year Plan" for the bio-industry, with strong backing from the National Development and Reform Commission. Over the past two years, Dacheng Bio-based Glycol has gained wide acceptance in China's unsaturated resin industry and is actively pushing forward its application in the chemical fiber sector.

Founded in 1994 and based in Hong Kong, Dacheng Biochemical Technology Group is Asia’s largest corn processing enterprise. With eight major product lines and global operations, the company has made significant strides in biotechnology. In 2007, through technological accumulation and independent innovation, Dacheng successfully established the world's first industrial-scale production line for bio-based glycols, with an annual output of 220,000 tons. The company plans to expand this capacity to 3 million tons within the next five years. Its product range includes bio-based resin alcohols, propylene glycol, and ethylene glycol, offering sustainable solutions for the post-oil era.

China's chemical fiber industry faces challenges, particularly high dependency on imported raw materials. As the world’s largest producer of chemical fiber, China accounts for 40% of global output. However, over 90% of its products rely on petroleum-based feedstocks, with raw material costs exceeding 80% of production expenses. Due to lagging domestic development, about two-thirds of the demand for raw materials is met through imports, posing risks to the industry’s stability and security.

In 2008, rising oil prices and RMB appreciation led to immediate difficulties for the domestic chemical fiber sector. The industry's volatility creates investment risks and hinders long-term growth. Additionally, the shortage of domestic oil production further exacerbates reliance on imports. In 2007, China imported approximately 5 million tons of ethylene glycol, with total apparent consumption reaching 6.57 million tons—equivalent to 76.65 million tons of crude oil. Without technological innovation, self-sufficiency in ethylene glycol remains difficult to achieve in the short term.

As traditional chemical fiber industries reach their growth limits, outsourcing raw material sourcing and market operations poses serious risks. Rising input costs and currency fluctuations threaten the sustainability of the entire supply chain. To address these issues, one solution involves extending the industrial chain globally by investing in raw material production in regions like the Middle East or India. Another approach is adopting the "Technological Innovation, Industrial Upgrading, Circular Economy, and Environmental Friendliness" strategy proposed by the China Chemical Fiber Industry Association.

The 21st century marks the rise of the biotechnology (BT) industry, where renewable resources such as plants, algae, and agricultural waste are being transformed into valuable products like fuel ethanol, biodiesel, and fine chemicals. Companies like DuPont and Cargill have already introduced bio-based fibers, such as PTT and PLA, which are gaining popularity in the chemical fiber sector.

China's national policies support this shift, with the "Eleventh Five-Year Plan" for bio-industries emphasizing the replacement of fossil materials with bio-based alternatives. The plan also encourages the use of biotechnology to upgrade traditional industries and reduce environmental impact.

By integrating bio-based polyols into the chemical fiber industry, China can create a more sustainable and competitive supply chain. These bio-based materials are not just substitutes but catalysts for broader technological and industrial transformation. From raw material development to product design, every stage offers opportunities for innovation and value addition.

Dacheng Group has pioneered several methods for producing ethylene glycol, including coal gasification and fermentation-based processes. Their bio-based glycol technology uses renewable feedstocks such as corn, wheat, potatoes, and sweet sorghum, reducing environmental impact while maintaining cost efficiency.

One of Dacheng’s most promising innovations is the development of PDT polyester, a novel copolyester derived from bio-based ethylene glycol. This material exhibits superior dyeing and spinning properties, with lower melting and processing temperatures compared to conventional PET. It also enables the production of ultra-fine and deep-stained fibers, making it ideal for advanced textile applications.

Looking ahead, the integration of biomass into the polyester industry presents a viable path toward a greener future. Materials like polylactic acid (PLA) and polybutylene succinate (PBS) are already showing promise, with applications ranging from biodegradable plastics to high-performance textiles.

With continued research and development, the dream of a fully bio-based chemical fiber industry is becoming increasingly achievable. By leveraging renewable resources and cutting-edge technology, China is positioning itself at the forefront of the global green industrial revolution.

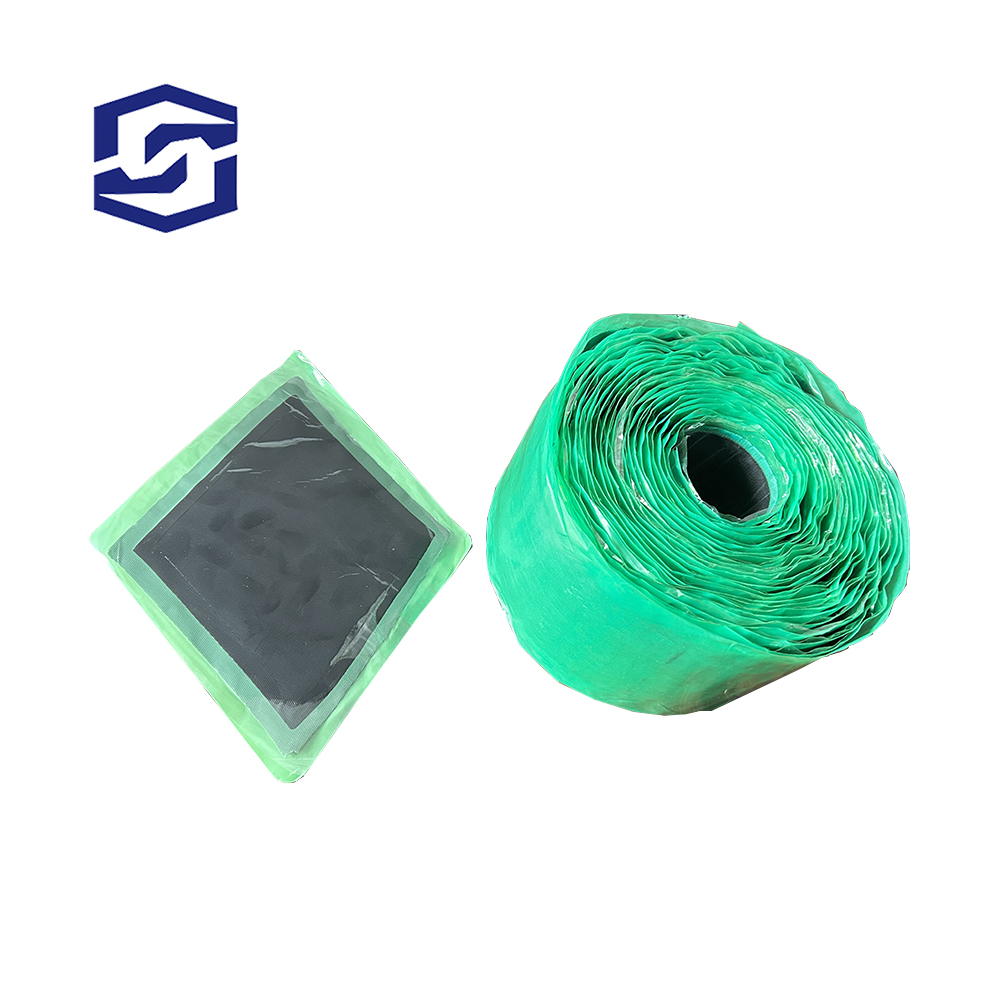

SL rubber repair series products are widely used, mainly used for rubber products and polyurethane and other elastomer damage repair.

Â

Such as: repair of various damage of conveyor belt, repair of wear resistant pipe lining damage, sealing of conveyor belt joints, cold patching of cables, coating of turbine blades, protection of belt buckles, and other kinds of rubber products.

Â

rubber repair,repair strip,conveyor belt repair strip,conveyor belt rubber repair,patch

Hebi Shuanglian Trading Co., Ltd. , https://www.slwearrubber.com