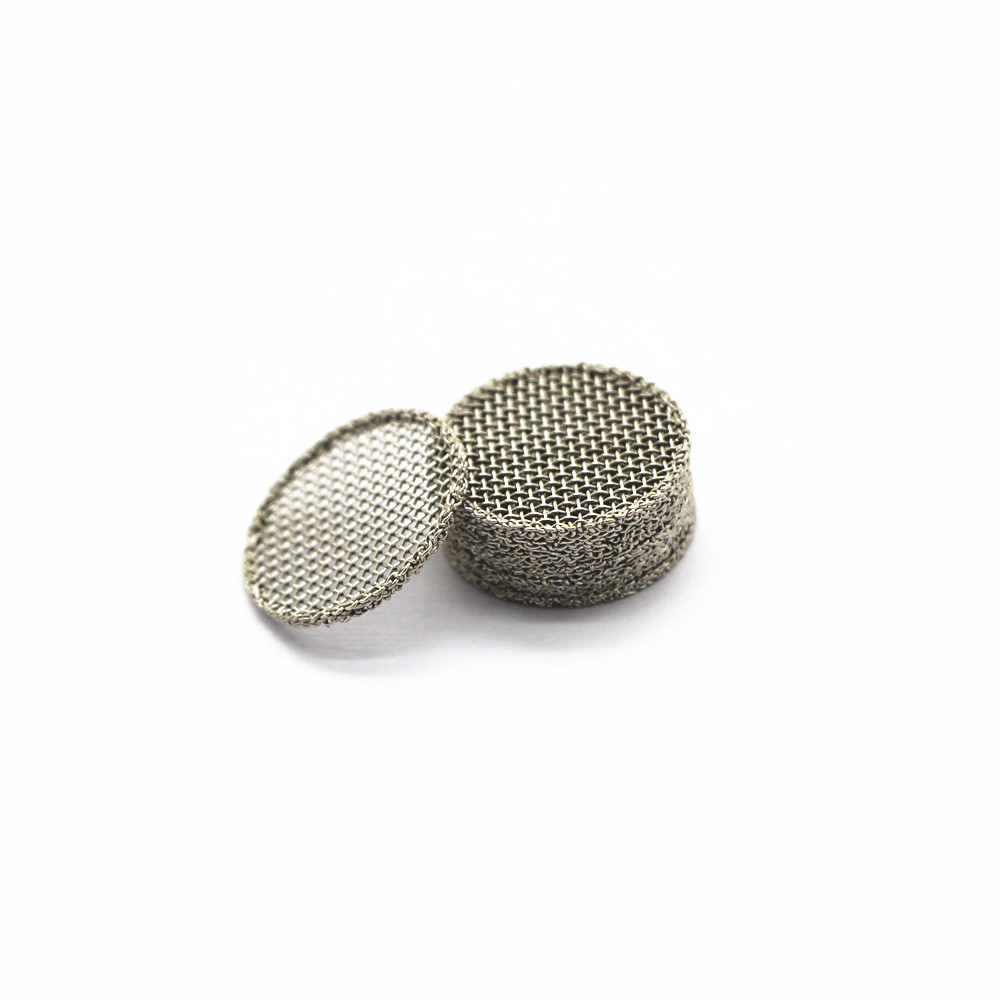

Wire mesh filter disc are commonly used in screen changers for filtration and separation in the industry of oil, chemistry, medical, food, water treatment etc. Single layer or multi-layer is acceptable and layer construction is depending on application and requested grade of filtration. Wire mesh filter disc Another name: wire mesh disc , filter disc Raw material :Stainless Steel Wire Mesh , Dutch wire mesh, copper wire mesh ,perforated wire mesh ,steel wire mesh , aluminum wire mesh etc. Type :single layer ,double layer and multilayer Material of package edge :stainless steel sheet , aluminum sheet ,copper sheet Shape :round ,square, rectangle, waist shape ,and oval etc. Features of filter disc 1, High filtration efficiency. 2,High temperature resistance. 3, Made in various materials, patterns and sizes. 4, Durable and long life working. 5, Strength and easily cleanable. 6, Available in screening and filtering in acid, alkali conditions. Application : It is suitable for distillation, absorption, evaporation and filtration in petroleum, oil refining, chemical industry, light industry, metallurgy, machinery, ship, automobile tractor and other industries to eliminate fog drops and liquid foam entrainment in steam or gas, as well as air filter on automobile tractor. Wire Mesh Filter Disc,Stainless Steel Mesh Filter Discs,Sintered Mesh Filter Disc,Wire Mesh Disc Suzhou Haoxiang Screen Stencil Products Co.,Ltd , https://www.haoxiangwiremesh.com

The machine is ideal for industrial applications where high precision and efficiency are required. It supports a wide range of materials and customizations, making it suitable for diverse manufacturing environments. With its intuitive control system and robust design, the SB50CNC is a reliable choice for modern tube bending operations.

---

(Word count: 576)

Specification/Model

SB50CNC

Notes:

1. Minimum bending diameter depends on the pipe size.

2. Maximum bending diameter can be customized based on customer needs.

3. Maximum mandrel length can also be adjusted according to requirements.

Maximum Bending Capability

Φ50mm × 3mm

Maximum Bending Radius

R250mm

Minimum Bending Radius

R20mm

Maximum Bending Angle

190°

Maximum Feeding Length

2600mm

Feeding Method

Direct Feeding / Clamping Feeding

Working Speed

Bending Speed

Up to 85°/s

Rotary Speed

Up to 200°/s

Feeding Speed

Up to 1000mm/s

Working Accuracy

Bending Accuracy

±0.1°

Rotary Accuracy

±0.1°

Feeding Accuracy

±0.1mm

Data Input Method

1. Axis X, Y, Z

2. Working Value Y, B, C

Bending Method

1. Servo Bending (1kW, more than 3 axes)

2. Hydraulic Bending

Power of Rotating Servo Motor

750W

Power of Feeding Servo Motor

1kW

Maximum Number of Bending Groups

12 or 33

Maximum Storage Components

330 or 125

Motor Power

7.5kW

Oil Pressure

12 MPa

Machine Dimensions

4900 x 1300 x 1300 mm

Weight

2500kg

Bending Aluminum Tubing/Bending Stainless Steel Tubing/Bending Steel Tubing

Here is a rewritten and improved version of the provided content in English, with additional details to make it more natural and comprehensive:

---

Maximum Bending Angle: 185°

Number of Pipe Fittings That Can Be Set: 16

Data Input Mode: Y.B.C

Rotary Servo Motor Power: 400W

Feeding Servo Motor Power: 1.5kW

Machine Dimensions: 3500 x 1550 x 1050 mm

Trademark: CAOS

Transport Packaging: Wooden Crate

Model Specification: SB50cNC

Origin: China

This machine is designed for precision bending of various types of tubing, including aluminum, stainless steel, and steel. It features advanced CNC technology that ensures accurate and efficient bending operations. The system supports multiple pipe fitting configurations and offers user-friendly programming through a visual interface.

Key features include:

- **Automatic power recognition** for both the machine and workpiece, ensuring smooth and high-quality processing.

- **Slow return core mechanism**, which improves the appearance of the bent angle.

- **Computer-controlled operation**, making the process simple, fast, and precise.

- **Visual programming system**: users can draw and modify pipe shapes on the screen, enhancing ease of use.

- **Rebound testing** to compare material properties and optimize bending results.

- **Single-step debugging function** for detailed observation of pipe deformation during die trials.

- **Automatic die drawing** to assist in product development.

- **Comprehensive diagnostics**: checks hydraulic, electrical, and drive systems, and automatically detects faults.

- **Production management features** such as password protection, working hours tracking, and quantity recording.

The SB50CNC model is known for its reliability and performance. Here are some key specifications: